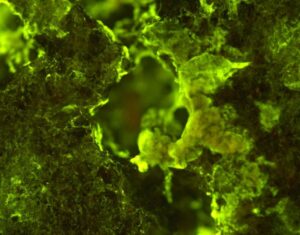

Earth-bound mining companies sometimes use microbes to extract valuable minerals from rock. About 20% of the world’s copper and gold production is aided by rock-chewing bacteria. Researchers began wondering how well they would fare in the vacuum and low gravity of space.

Earth-bound mining companies sometimes use microbes to extract valuable minerals from rock. About 20% of the world’s copper and gold production is aided by rock-chewing bacteria. Researchers began wondering how well they would fare in the vacuum and low gravity of space.

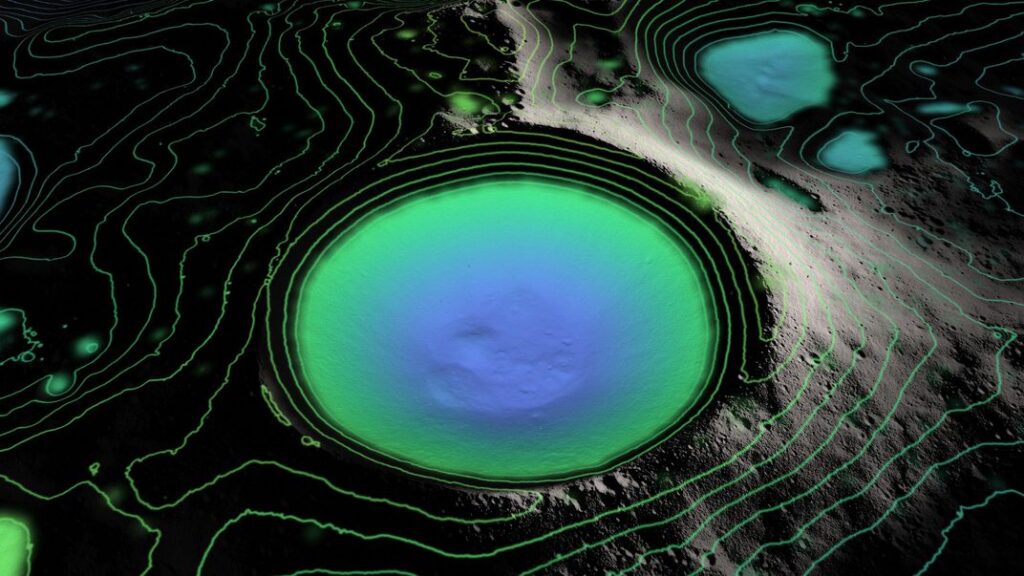

In a first-of-its-kind experiment in 2019, astronauts on the International Space Station last year activated a series of miniaturized, matchbox-sized mining devices with small blocks of basalt, a volcanic rock that is common on the Moon. Three types of bacteria were selected to munch on the rocks for about three weeks while spun in centrifuges mimicking gravitational conditions on the Moon, Mars and Earth.

Researchers measured how much iron, magnesium and a dozen other elements the bacteria pulled out of the rock samples. Of the three, one stood out: Sphingomonas desiccabilis. It displayed 70% efficiency in extracting neodymium and cerium, two so-called rare earth minerals.

“We were surprised that there was no significant effect of the different gravities on the biomining, given that microgravity is known to influence the behavior of fluids,” astrobiologist and study co-lead author Charles Cockell told Space.com.

Said Cockell:

I think we should continue exploring the types of microbes that would give us the best results in extracting useful elements from materials to be found in space, such as on asteroids, the moon and Mars, and we should continue to develop the technology for optimizing these sorts of biologically enhanced industrial processes in space.

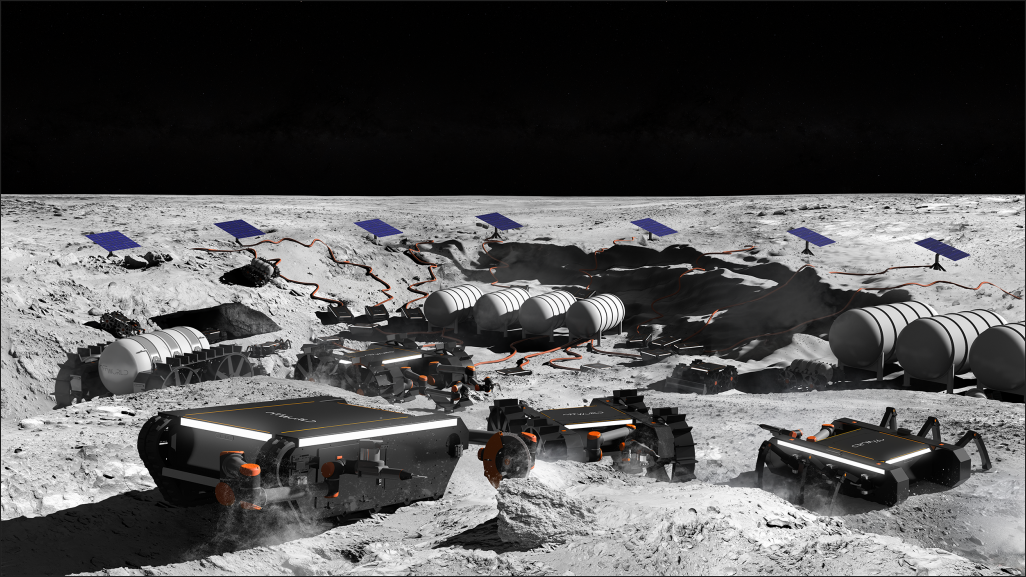

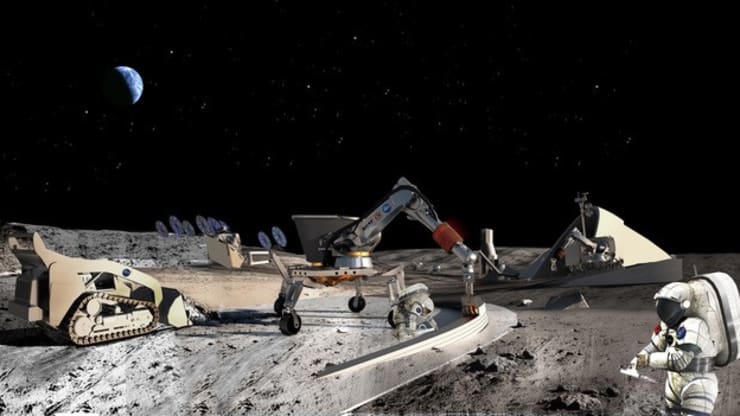

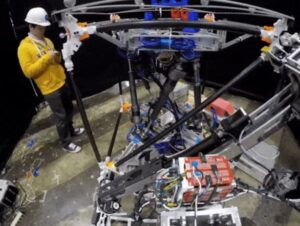

Foreseeable needs for space exploration exceed projected payroll-launch capacity, so NASA envisions the need for robotic manufacturing on the Moon. A newly funded project called The Assemblers envisions a swarm of robots fabricating solar arrays and undertaking other assembly tasks on the surface of the Moon or Mars.

Foreseeable needs for space exploration exceed projected payroll-launch capacity, so NASA envisions the need for robotic manufacturing on the Moon. A newly funded project called The Assemblers envisions a swarm of robots fabricating solar arrays and undertaking other assembly tasks on the surface of the Moon or Mars.