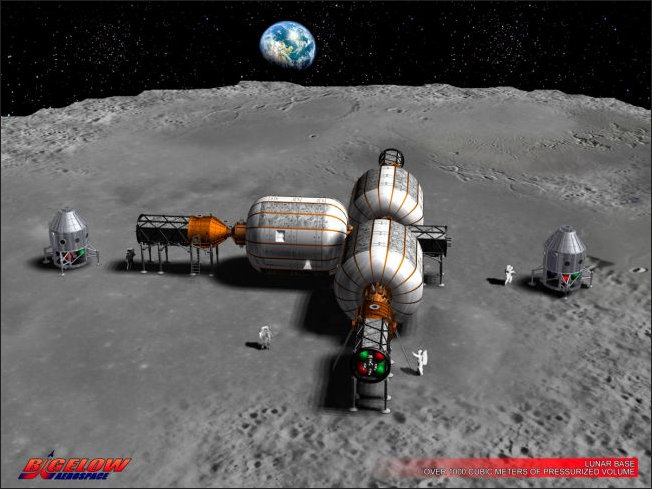

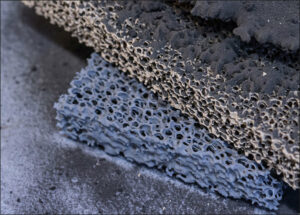

Early settlers on the Moon will need to protect themselves against radiation, which will entails covering habitats with meters-thick layer of protective regolith. Professor Matthias Sperl, with the German Aerospace Center, imagines the necessity of transforming loose dust into sturdy bricks. Because the Moon lacks the components of mortar to bind the bricks together, they will have to be unterlockable, similar to Lego toys.

Early settlers on the Moon will need to protect themselves against radiation, which will entails covering habitats with meters-thick layer of protective regolith. Professor Matthias Sperl, with the German Aerospace Center, imagines the necessity of transforming loose dust into sturdy bricks. Because the Moon lacks the components of mortar to bind the bricks together, they will have to be unterlockable, similar to Lego toys.

Given the economics of lifting building materials out of Earth’s gravity well, it would make far more sense fabricate the bricks on the Moon, said Sperl in an article in Horizon, the European Union research & innovation magazine, Using solar energy and 3D printing could bring down the cost tremendously.

Here’s how the economics shake out:

‘If you bring something up to the space station you may think about a cost between EUR 5 000 to EUR 10 000 to bring one kilogram of material. To such an order of magnitude you can easily add a factor of 10 if you go to the moon.

‘Imagine that you have a machine that you put on the lunar surface to build the bricks, something similar to the rovers we put on Mars. Such machines weigh about 200 kilograms, which would cost you roughly EUR 20 million. If you need to bring additional infrastructure such as shoveling devices, you can assume a cost of EUR 100-200 million.

‘Now imagine building bricks and other elements worth 10 tons of upload (material taken to space) on earth, as you will easily need a couple of thousand bricks for one building. To ship all of that to the moon, the estimated cost would be EUR 1 billion.

Of course, once you’ve paid to put machines on the Moon, they can build bricks to protect more than one habitat.